RIECO Dual Tunnel Diverter Valve

The RIECO Dual Tunnel Diverter Valve is a high-precision rotary diverter engineered for dilute and dense-phase

pneumatic conveying of powders and granules. Unlike flap or butterfly-style diverters—which introduce high wear,

leakage paths, and material degradation—the valve uses a dual parallel tunnel plug that rotates to align the

conveying path with the selected outlet, ensuring a fully unobstructed bore and minimal pressure drop.

The pressure-tight housing, stainless steel product-contact surfaces, and rapid rotary actuation make this valve

suitable for continuous-duty conveying, high switching frequencies, abrasive materials, and industries with

stringent hygiene or contamination control requirements.

Technical Model Matrix

| Model |

Pipe Size (NB) |

Switching Angle |

Max. Op Pressure |

Construction |

| DTDV 80NB |

80 mm |

36.6° |

3.5 bar(g) |

SS 304 |

| DTDV 100NB |

100 mm |

35° |

3.5 bar(g) |

SS 304 |

| DTDV 125NB |

125 mm |

35.5° |

3.5 bar(g) |

SS 304 |

| DTDV 150NB |

150 mm |

35° |

3.5 bar(g) |

SS 304 |

| DTDV 200NB |

200 mm |

34.8° |

3.5 bar(g) |

SS 304 |

Design and Operating Principle

The valve operates on a rotary plug mechanism fitted with two independent, full-bore tunnels. The design eliminates

constrictions in the conveying path, ensuring uniform air-solids flow velocity.

Operating Sequence:

-

Position A (Outlet–1 Aligned)

- Tunnel-1 is aligned with the inlet and Outlet A.

- Tunnel-2 remains isolated and sealed via static/dynamic elastomeric seals.

-

Transition

- A pneumatic actuator rotates the plug by approx. 35°.

- Rotation is completed in <1 second under standard pressure.

-

Position B (Outlet–2 Aligned)

- Tunnel-2 aligns with the inlet and Outlet B.

- Tunnel-1 is fully sealed off.

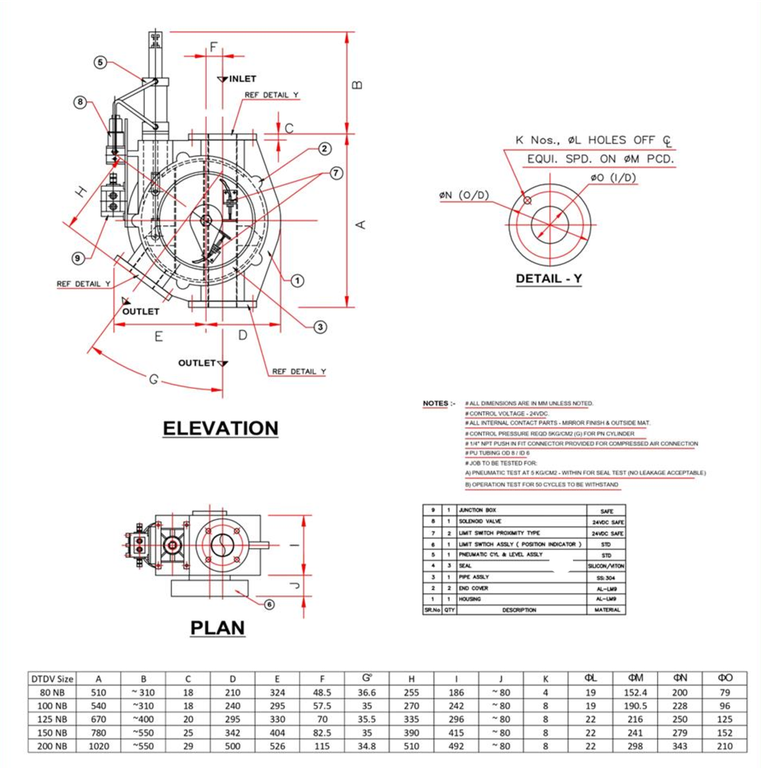

Dimension Chart

Major Components & Engineering Construction

| Component |

Engineering Description |

Material |

Design Advantage |

| Valve Housing |

Machined internal bore with precision SS insert for wear protection. |

Aluminium casting with SS liner |

High strength-to-weight ratio; pressure-tight up to 3.5 bar(g). |

| Pipe Assembly (Rotor) |

Dual-path plug with two independent conveying channels; precision-ground sealing surfaces. |

Stainless Steel 304 |

Ideal for abrasive, hygienic, and high-frequency switching applications. |

| Pneumatic Actuator |

Direct coupled to plug shaft; high torque for rapid switching. |

Pneumatic cylinder with linkage |

Ensures positive positioning and repeatable switching accuracy. |

| Sealing System |

Static and dynamic seals optimized for pressure containment and minimal leakage. |

Silicone / VITON |

Suitable for food, pharma, chemicals; low wear under cyclic duty. |

| Control & Feedback Package |

Solenoid valves, position sensors (proximity switch), junction box. |

Industrial-grade sensors |

PLC-ready, reduces control panel integration time. |

Performance Features

| Engineering Constraint |

DTD-P Feature |

Resulting Technical Benefit |

| Avoiding shear & attrition in fragile products |

Full-bore straight tunnels |

No turbulence zones; velocity profile remains uniform. |

| Preventing leakage under pressure |

Precision plug + elastomeric sealing |

Airtight sealing of non-active outlet; prevents reverse flow. |

| Reducing field maintenance |

Enclosed mechanism |

Minimal exposure of moving parts; extended MTBF. |

| Ensuring mechanical integrity under cyclic loads |

SS plug + reinforced housing |

Stable geometry and long operational life. |

Applications

Food & Beverage

- Material: Sugar, coffee beans, spices, flour blends

- Use Case: Line selection from silo to multiple packing stations

- Engineering Requirement: Hygienic surface finish, low shear

- Compatibility: Meets cGMP design expectations

Pharmaceutical

- Material: APIs, excipients, granules

- Use Case: Post-blending routing to compression or coating lines

- Key Requirement: No cross-contamination between batches

- Compatibility: SS contact parts; seal options for cleanroom use

Plastics & Polymers

- Material: PVC / PE / PP granules

- Use Case: Routing to multiple extruders or day bins

- Engineering Requirement: No pellet chipping; withstands cyclic switching

Chemical & Mineral Processing

- Material: Cement, ash, alumina, pigments

- Use Case: Diverting to alternate reactors or storage bins

- Key Requirement: Abrasion resistance; pressure integrity

Technical Model Matrix

| Model |

Pipe Size (NB) |

Switching Angle |

Max. Op Pressure |

Construction |

| DTDV 80NB |

80 mm |

36.6° |

3.5 bar(g) |

SS 304 |

| DTDV 100NB |

100 mm |

35° |

3.5 bar(g) |

SS 304 |

| DTDV 125NB |

125 mm |

35.5° |

3.5 bar(g) |

SS 304 |

| DTDV 150NB |

150 mm |

35° |

3.5 bar(g) |

SS 304 |

| DTDV 200NB |

200 mm |

34.8° |

3.5 bar(g) |

SS 304 |

Technical Performance Data

| Parameter |

Specification |

| Conveying Modes |

Dilute & Dense Phase |

| Maximum Pressure |

3.5 bar(g) Op. (6 bar Design.) |

| Operating Temperature |

(-)20 to (+) 80°C |

| Product Contact Material |

SS304 |

| Housing Material |

Aluminium Casting + SS Insert |

| Leakage Class |

Air-tight |

| Area Rating |

Safe area Std |

| Switching Cycle Time |

2-3 second |

| Max Hardness of Powder |

2 MHO |