Image and Briefs

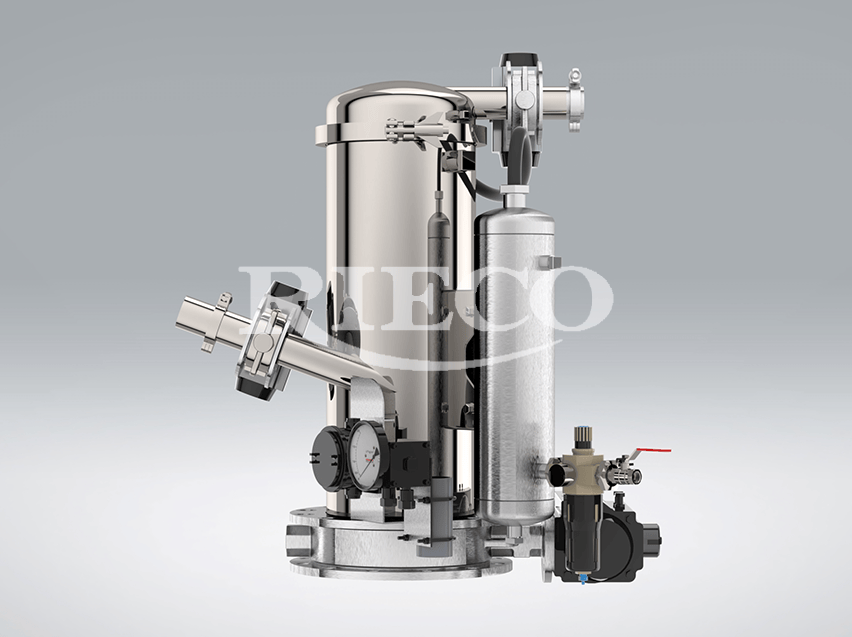

Transfer Powder and Bulk Solids with Ease!

As manufacturing of food, pharmaceuticals, fertilisers, or chemicals must

adhere to the highest standards of hygiene and safety, RIECO, a leading

Powder Transfer System supplier, offers the POWTRAN series PTS loader

to meet all your powder transfer needs.

Powder handling systems by RIECO are designed to be extraordinarily

effective for transfer dry and wet powders and granules.

With POWTRAN, the future of powder handling and bulk solids handling is

here. Experience this difference in your conveying operations today.

Model Description

| POWTRAN® Model | Charge Volume (litres/cycle) | Total Loader Height (mm) | Weight of Loader (Kg) (Without valves) | Conveying Pipe Size (NB) | Discharge Size (NB) | Filter Area (m²) | Air Consumption (Nm³/hr) at 6–7 bar |

|---|---|---|---|---|---|---|---|

| T-150 | 2.6 | ~750 | ~40 | 25 NB | 150 | 0.5 | 2–10 |

| T-200 | 6.5 | ~800 | ~45 | 40 NB | 200 | 1.152 | 2–10 |

| T-250 | 12.5 | ~850 | ~55 | 50 NB | 250 | 2.56 | 2–10 |

| T-300 | 21.0 | ~1100 | ~70 | 65 NB | 300 | 3.6 | 2–10 |

| T-350 | 33.5 | ~1250 | ~85 | 80 NB | 350 | 6.336 | 2–10 |

Features

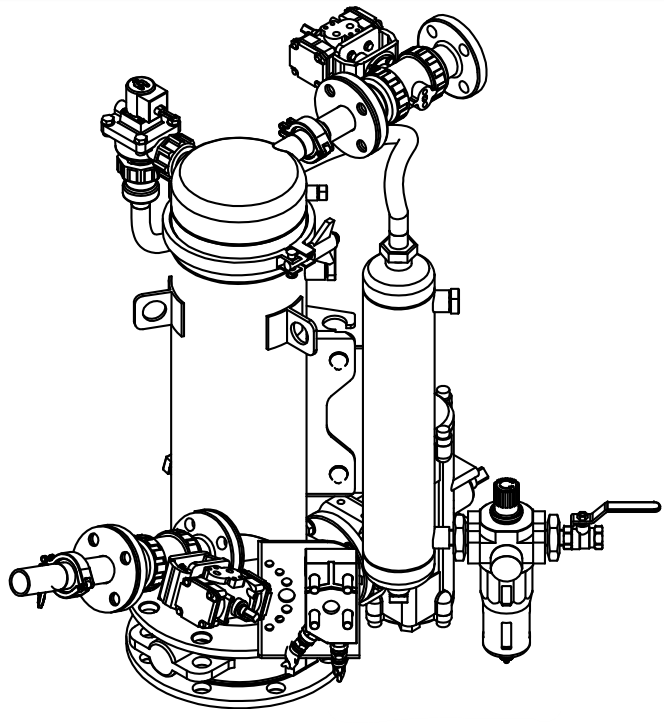

- Quick removable clamps for hoses & easy dismantling of components.

- Pick-up lance with flexible and transparent hoses of PVC/ PU material for visibility and conveying of material.

- ATM valve helps in avoiding frequent on/off of vacuum pumps, between the batch.

- Adjustable air amplifier allows fine-tuning of material flow rate.

- Loading or Unloading from all process equipment (including reactors, dryers, and centrifuges)

Benefits

| User Challenges | POWTRAN® Feature | Tangible Benefit |

|---|---|---|

| Operator Exposure & Dust | Fully Enclosed, Dust-Free Operation | Protect operators and maintain compliances. |

| Cross-Contamination | cGMP & Hygienic Design | Quick cleaning and zero carryover between batches. |

| Manual Handling & Delays | Automated, Repeatable Cycles | Reduces manpower and increases batch throughput by up to 70%. |

| Space Constraints | Compact, Hose-Based Layout | Easily routed around existing machinery with minimal footprint. |

| Product Loss | Pulse-Jet Filter Cleaning | Maximizes powder recovery, improving yield and efficiency. |

Applications

| Industry | Material / Process |

|---|---|

| Pharmaceutical | API, excipients, granules |

| Food & Beverages | Flour, sugar, spices, milk powder |

| Spice Manufacturing | Chili, turmeric, coriander powder |

| Specialty Chemicals | Pigments, resins, catalysts |

| Battery Manufacturing | Cathode / anode powders |

*Applications above are indicative. Material-specific trials recommended for optimal design selection.*

POWTRAN® Model Characteristics (Ready Reckoner)

| POWTRAN® Model | Charge Volume (litres/cycle) | Total Loader Height (mm) | Weight of Loader (Kg) (Without valves) | Conveying Pipe Size (NB) | Discharge Size (NB) | Filter Area (m²) | Air Consumption (Nm³/hr) at 6–7 bar |

|---|---|---|---|---|---|---|---|

| T-150 | 2.6 | ~750 | ~40 | 25 NB | 150 | 0.5 | 2–10 |

| T-200 | 6.5 | ~800 | ~45 | 40 NB | 200 | 1.152 | 2–10 |

| T-250 | 12.5 | ~850 | ~55 | 50 NB | 250 | 2.56 | 2–10 |

| T-300 | 21.0 | ~1100 | ~70 | 65 NB | 300 | 3.6 | 2–10 |

| T-350 | 33.5 | ~1250 | ~85 | 80 NB | 350 | 6.336 | 2–10 |

Performance Parameters

| Characteristic | Specification |

|---|---|

| Capacity Range | 500 to 3000 Kg/hr |

| Bulk Density Range | 350 – 900 Kg/m³ |

| Particle Size Range D50 (passing through %) | 100 microns to 10 mm (subject to particle shape) |

| Max Conveying Distance | 25m (including horizontal (15m) & vertical (10m)) with a maximum of 3 bends |

| Moisture Content Limit | <2% |

| Temperature | Atmospheric |

| Gaskets & Seals | Food Grade (FG Silicon) |

| Required Clearance above the PTS | Xx m |